It’s a fact of life in any industry that technologies will evolve over time. So it is with the diaphragms that are an integral component in – and

actually give the name to – Wilden? Air-Operated Double-Diaphragm (AODD) pumps. When Jim Wilden invented this landmark pumping technology in 1955, there was one diaphragm material option. Over the years, though, the menu of diaphragm designs

and materials of construction has expanded to the point where there are options today that can be dialed in for use in even the most specific or unique liquid-handling applications.

It’s a fact of life in any industry that technologies will evolve over time. So it is with the diaphragms that are an integral component in – and

actually give the name to – Wilden? Air-Operated Double-Diaphragm (AODD) pumps. When Jim Wilden invented this landmark pumping technology in 1955, there was one diaphragm material option. Over the years, though, the menu of diaphragm designs

and materials of construction has expanded to the point where there are options today that can be dialed in for use in even the most specific or unique liquid-handling applications.

The initial AODD pump diaphragm was a pie-shape design constructed of rubber compounds like neoprene and Buna-N. Rubber was the obvious choice at that time because it was the only material that could withstand the repeated flexing that is inherent in

diaphragm operation. It was discovered that after extended use, the pie-shape transformed into a more convoluted shape. Seeing as this was the more natural form, the first attempt to improve on basic pie-shaped rubber came with the invention of the

Ultra-Flex diaphragm design, a convoluted diaphragm shape – which led to extending the life of the diaphragm more than the traditional pie-shape.

To help extend the application and temperature range of the diaphragms, thermoplastic elastomers, or TPEs, were the next frontier. With

TPE materials such as Santoprene?, Hytrel?, Geolast? and Polyurethane, Wilden TPE diaphragms were able to better handle abrasion, chemical resistance, fats/oils, slurries and other materials while also improving diaphragm flex life.

However, the pie-shape design of these diaphragms still had its shortcomings. For one, it needed to be inverted when, which required a fair bit of effort and force to ensure proper installation. This led to the next iteration of the diaphragm design,

the EZ-Install. True to its name, the EZ-Install featured a new convoluted shape that eliminated the need to invert the diaphragm during installation, making it easier, faster and

safer to install.

After the release of EZ-Install diaphragms, the next advancement was adding PTFE diaphragms to the portfolio. Wilden’s

first PTFE models featured smaller inner and outer pistons, reduced-stroke operation (hence, lower flow rates) and a rubber backup diaphragm. Despite their advantages, these early models had poor flexibility since the PTFE was more rigid, like

a Tupperware-type material. Over time, the evolution of PTFE materials allowed the creation of full-stroke models that could use the same size outer and inner pistons as the rubber and TPE styles for 20% to 40% increased flow rates. These models

also have a TPE backup diaphragm for even better flexibility.

As Wilden continued to release additional diaphragm materials and designs, it became obvious that these advancements were having a profound impact on diaphragm maintenance while leading to increased performance and diaphragm life. Therefore, the Wilden

engineering team decided to focus on improving their traditional diaphragm design.

For example, traditional pie-shape diaphragms have an inner and outer piston. With the outer piston and diaphragm meeting point being a vulnerable spot, a lot of diaphragm ruptures and leaks occur here due to outer piston abrasion. It also can be

a trap area that can increase wear when pumping abrasive fluids or harbor bacteria in hygienic applications.

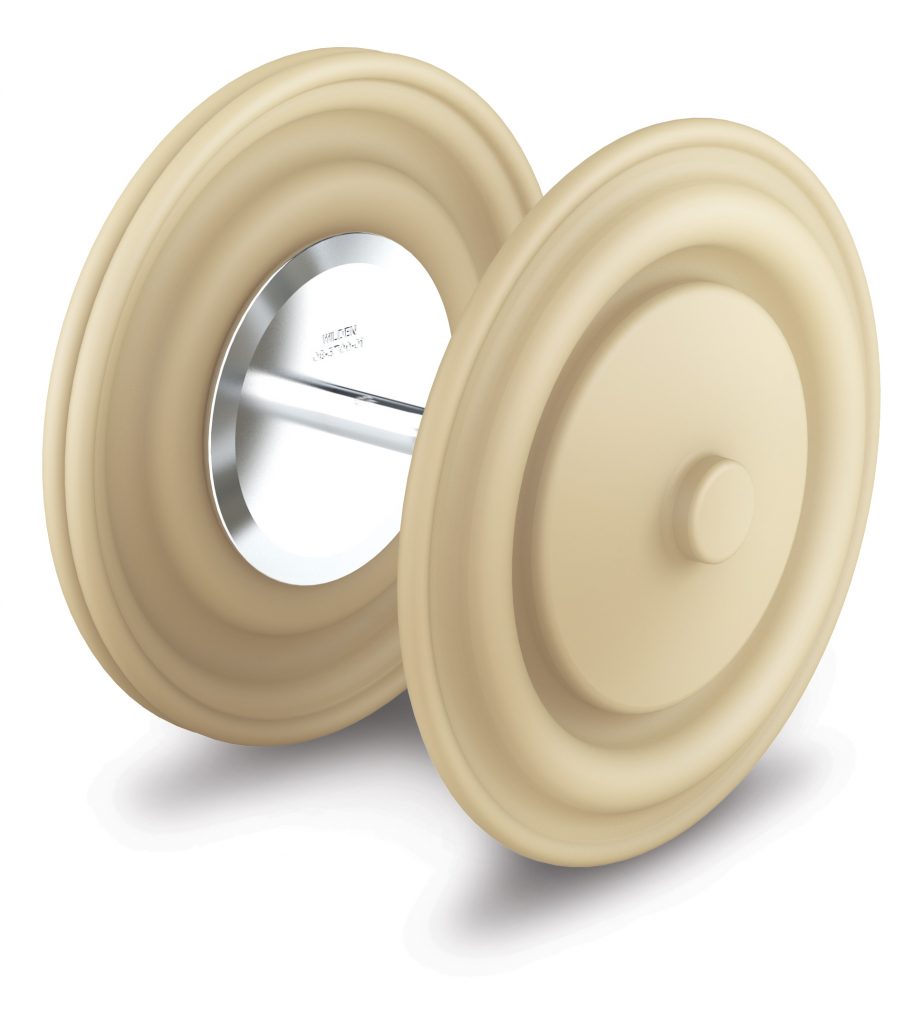

This leads to the latest advance in TPE diaphragms, the patented Chem-Fuse and Pure-Fuse Integral Piston Diaphragm (IPD) design. The IPD design features a configuration that encases the outer piston within the diaphragm

material, eliminating the outer piston abrasion and trap area. This gives the Chem-Fuse and Pure-Fuse diaphragms significantly longer life than any other diaphragm available today. Chem-Fuse is perfect for abrasive chemical applications while

Pure-Fuse is certified and excellent for hygienic and sanitary clean-in-place (CIP) applications.

With a global shift towards energy-efficient solutions and best-production practices, Wilden’s focus has evolved to address these concerns while still maintaining the high performance, quality and customer satisfaction for which Wilden is known.

This is why Wilden is dedicated to delivering diaphragm solutions that are more simple, reliable and efficient when compared to competitive options.

To learn more about Wilden diaphragms,

click here.