Almatec Products

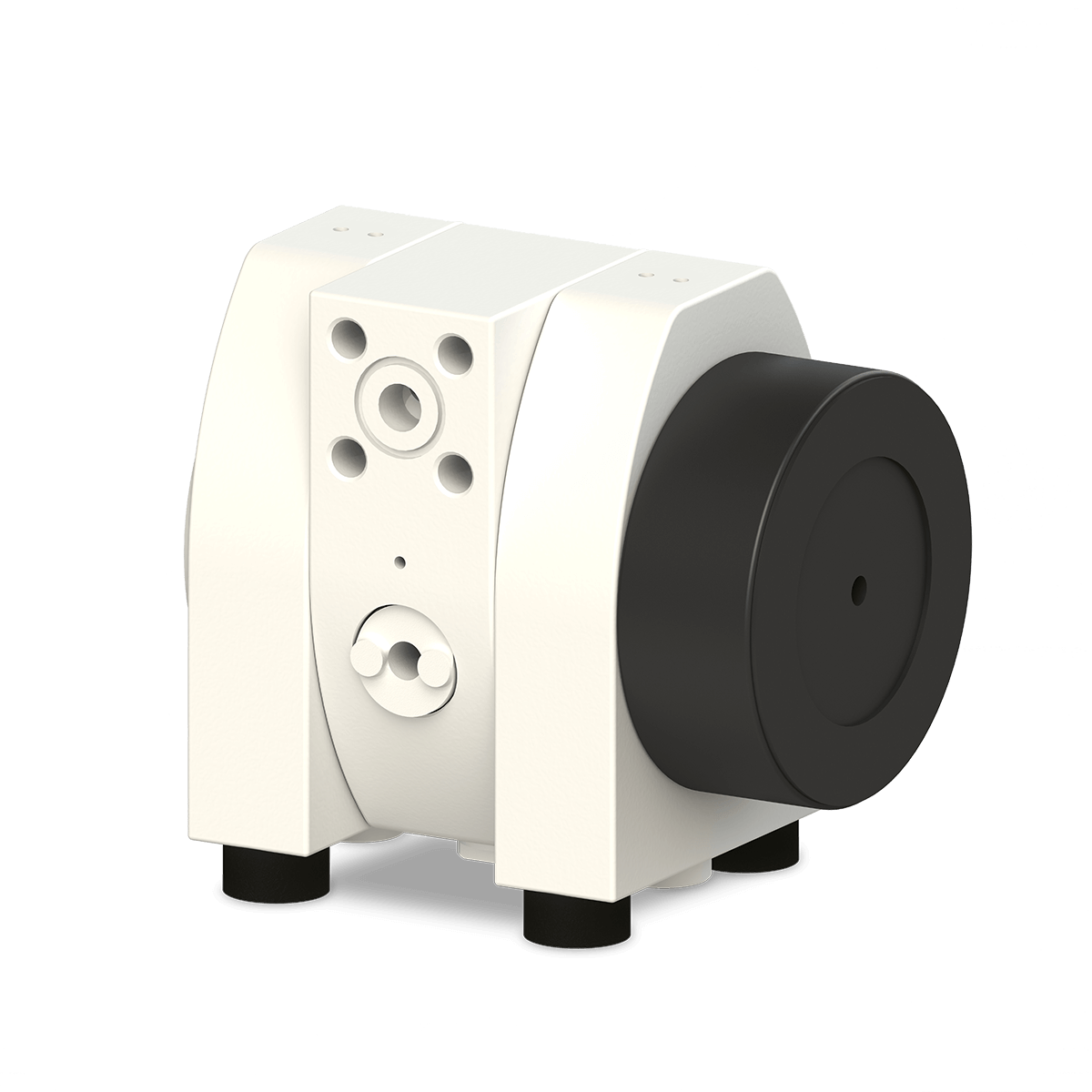

A respected worldwide leader in AODD pumps

Almatec? pumps meet or exceed industry quality requirements and incorporate the standard-setting features and benefits our customers have come to demand.

View Our ProductsTechnology

View AllPlastic Pumps

View AllSpecialty Pumps

View AllPulsation Dampers

View AllAlmatec Markets

A respected worldwide leader in AODD pumps

Almatec offers an extensive product portfolio that features sophisticated and economical solutions for all your critical applications.

View Our MarketsOptions Meeting Special Application Requirements

A variety of quality optional equipment completes the Almatec pump program, and allows a precise set up for your specific application.

Find more information about Almatec Pulsation Dampers

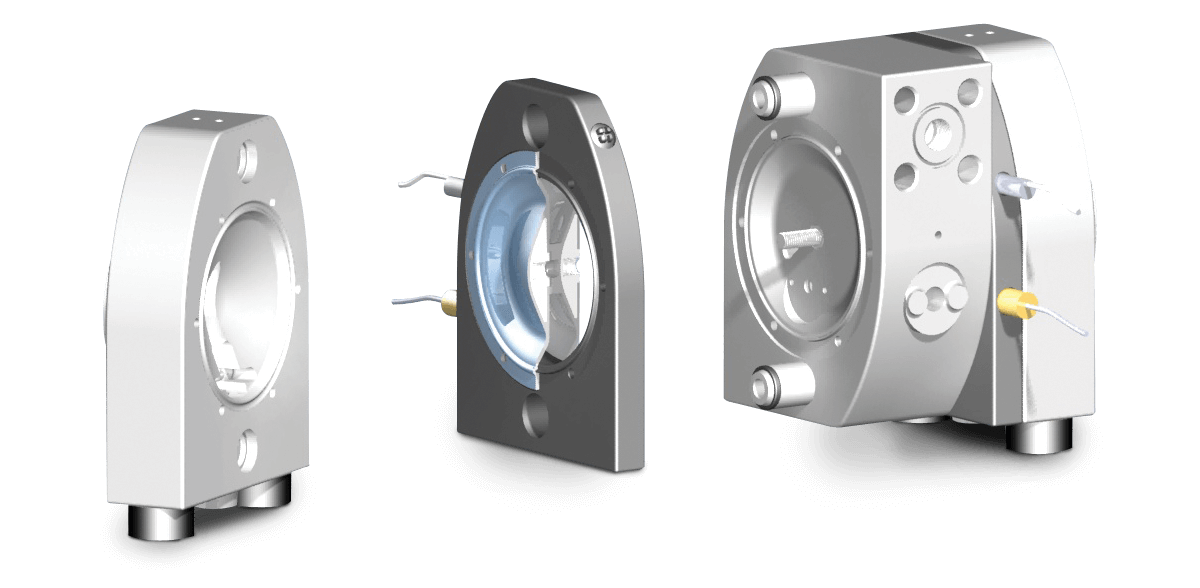

Barrier Chamber System (Code BS)

The Almatec barrier chamber system meets high-safety requirements. The individual diaphragm is replaced by two diaphragms arranged in tandem with a barrier chamber of conductive PE between them and filled with non-conductive liquid. A change in conductivity of the barrier liquid is detected by sensors and signaled to a controller, which triggers an alarm or disconnects the pump.

Pump series:

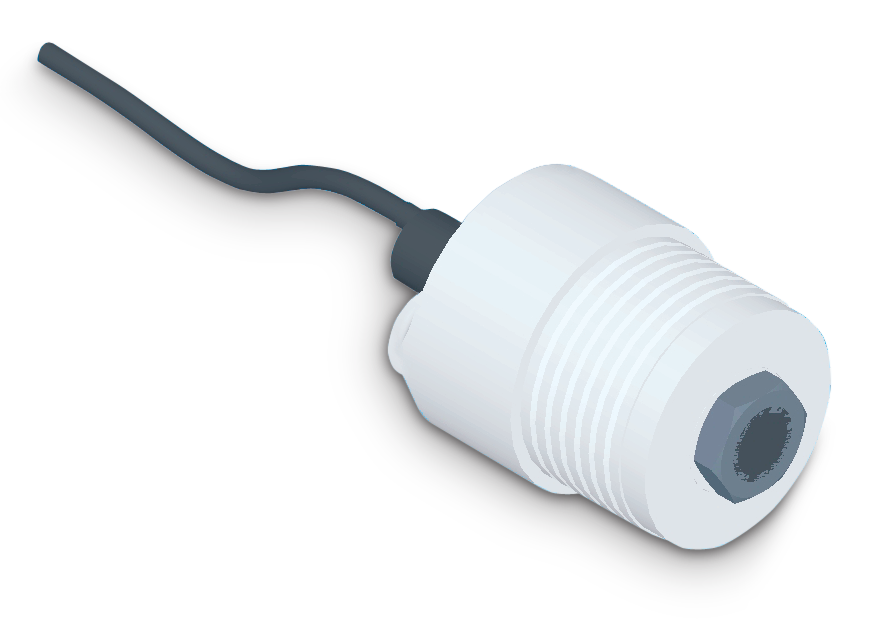

Stroke Counting (Code C)

Almatec air-operated diaphragm pumps can be used continuously (24-hour operation) or intermittently for hours, for minutes or for an exact defined number of strokes. To accurately count the strokes, a sensor can be installed in the pump's center housing (also available as pneumatic version).

Diaphragm Monitoring (Code D)

A capacitive sensor installed in the pump muffler detects all liquids and in case of a diaphragm rupture it outputs a corresponding signal to a controller which then triggers an alarm or disconnects the pump via a connected solenoid valve.

Flange Connection (Code F)

According to recognized industry safety standards, all E-Series pump sizes from E 15 to E 50 can be equipped with thread bushings and flange O-rings for flange connections DIN or ANSI / PN 10. For the AH Series pumps, the flange connection DIN or ANSI / PN 16 is standard.

Pump series:

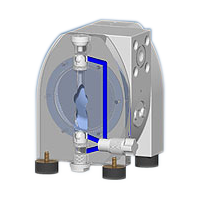

Draining System (Code R)

E-Series pump sizes E 15 to E 50 are available with a special Almatec draining system consisting of a bypass system in the side housings that can be activated easily either via hand-operated valves or pneumatically. In this way, the pump and piping can be drained without having to be dismounted. The amount of cleaning agent and solvent required when changing products is considerably reduced, and this greatly reduces environmental pollution. For metal CHEMICOR pumps, another constructive solution is available. Ball lifters – which are turnable by hand – are fitted to the four ball valves. By turning the handles, the ball valves are lifted out of their seats.

Pump series:

Pneumatic Expansion Compensation (Code EC)

Temperature changes can cause thermal expansion to occur in air-operated double-diaphragm (AODD) pump units engineered with plastic housings and metallic connecting elements. Operating in wide temperature ranges – including many PTFE pump standard applications – can lower the tension of the connecting elements. Therefore, Almatec has introduced an “Expansion Compensation” option for its line of E-Series AODD pumps (code EC for E-Series pump sizes 15/25/40/50). Learn more about the technical background, the Almatec solution and your benefit in the Flyer.

Pump series:

Special Diaphragms (Code L and P)

For the use of the pumps in the device group IIC (European ATEX regulation) without flanking measures diaphragms made of conductive PTFE/ EPDM compound are available (code L). For liquids with increased diffusion tendency (e.g. benzene, solvents) PTFE/EPDM compound diaphragms made of modified PTFE are obtainable (code P).

Pump series:

EC1935/2004 Certification (Code H)

Since certifications are an important aspect in the hygienic market, an EC1935/2004 conformity declaration can be issued for Almatec pumps with PTFE internals for the applicability of the pump material for food contact.

Pump series:

USP Class VI Certification (Code USP)

After receiving an increasing number of requests to state “USP Class VI” conformity for the wetted pump materials, Almatec has introduced the “Option Code USP” for defined material types. Whenever ordering such a pump, the customer can be sure to receive a clearly marked pump together with an according certificate. Please contact us for more information about the concerned pump material codes.

Pump series:

Transport Carts

Many industrial applications need not only stationary air-operated diaphragm pumps but also mobile pumping units (e.g. for use as an emergency pump, as a short-dated replacement for a pump to be repaired or for decanting between two containers). For these purposes, a transport cart is available.